Solder paste is a new type of welding material that came into being with SMT. It has a certain viscosity at room temperature and can initially stick electronic components to a predetermined position. At the welding temperature, as the solvent and some additives evaporate, the soldered components and printed circuit pads are welded together to form a permanent connection.

Glue dispensing syringes are commonly used accessories in the glue industry. Whether it is an automatic dispensing machine or a manual dispensing machine, glue dispensing syringes are basically required as dispensing accessories. Now share the application of solder paste industry and glue dispensing syringes:

1、Definition of solder paste

• Main ingredients: tin powder, flux, surfactant, thixotropic agent.

• General solder paste tin powder 63Sn/37Pb (SE48-M954-2 contains Sn, PB, Ag, Sb);

• According to the composition of the flux, it is divided into: rosin solder paste, no-clean solder paste, water-soluble solder paste;

• According to the reflow temperature, it is divided into: high temperature solder paste, room temperature solder paste, low temperature solder paste;

• Environmental protection classification: leaded, lead-free, halogen-free.

• Appearance: gray, paste;

• Viscosity: about 50000-60000;• Storage conditions: 5℃ -10℃ / (-5℃-10℃);• Storage time: 6 months;

• Melting point: high temperature solder paste melting point: 210℃ -270℃;

• Low temperature solder paste: 135℃ -180℃ The welding of high temperature solder paste is completed in the reflow soldering equipment;

• Welding temperature: 245℃-260℃, time 20-50 seconds;

• Reflow soldering is divided into: heating zone, preheating constant temperature zone, welding zone, cooling zone, and the completion time of reflow soldering is 4-7 minutes;

• Function: welding, conductive, shockproof;

• Features: heating soldering, precision soldering of PCB surface resistors, capacitors, ICs and other electronic components. It has the characteristics of moisture-proof, water-resistant, ozone-resistant, weather-resistant and conductive.

02. Common applications of solder paste

Applications

Solder paste is mainly used in LED semiconductors, photovoltaic products, cameras, connecting wires, etc., and mainly plays the role of welding, shockproof, and conductive.

Use

Mainly used for SMT, PCB board welding and tinning of electronic component pins to achieve high reliability, high stability, and weldability.

Application industries

• LED semiconductors: used for LED chip packaging and power device packaging such as diodes; high-power LED lamp beads are soldered to aluminum substrates;

• Photovoltaic products: used for inner layer bonding of photovoltaic connectors;

• Cameras: welding of camera pins and motherboards;

• Connecting wires: used for conductive welding of wires and connectors;

• Suitable for welding of various SMD electronic components.

03. How to use solder paste

• This product should be stored in a low-temperature environment. It should be placed at room temperature for 3 to 4 hours before use;

• Before use, clean the surface of the component to be bonded, remove the oil and other impurities on the surface (volatile organic solvents can be used, such as ethanol, acetone). Apply the solder paste to the solder joints to be bonded, and then place the components accurately on the solder joints, and place them for high-temperature soldering in reflow soldering.

• Send the coated components to the reflow soldering through a conveyor belt for 4-7 minutes, and they can be soldered and have a conductive effect;

• After opening, seal it well before use, and store it at low temperature to prevent the product from absorbing moisture and affecting the quality;

• Due to the high viscosity of the solder paste and the syringe packaging form, as well as the different equipment and usage methods of different customers, it is normal to have 1-2g of residual solder paste in the syringe at the end;

04. Packaging, storage and transportation of solder paste

• This product is stored at low temperature of -5℃-10℃. The effective storage period of the product is 6 months. If it meets the standards, it can still be used after re-inspection after the expiration date;

• Packaging: bottle and syringe packaging.

• Bottle: mostly used in 500g white jars.

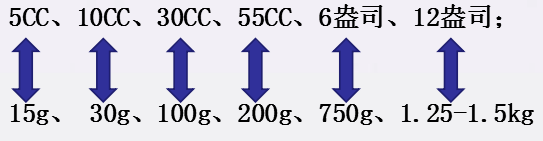

• Syringe: This product is packaged in 5CC, 10CC, 30CC, 55CC transparent syringes, 6 ounces, 12 ounces white syringes, and can be negotiated and specified according to user needs;

• Needle: Currently mainly used TT needle (JD514, 516) or plastic seat stainless steel needle or all stainless steel needle (18-25G needle);

• This product is stored and transported as non-dangerous goods.

• In the solder paste industry, the weights of syringe packaging corresponding to the respective sub-packaging are as follows (approximately 3 times the capacity of the syringe):

05. Packaging and degassing methods

Packing method: conventional small syringe: packing from the head; packing from the tail is mainly for making samples;

Degassing method: degassing is not allowed. Because the specific gravity of tin powder is heavier than that of rib flux, degassing will cause the tin powder to separate from the rib flux and sink to the bottom, causing the solder paste to delaminate.

The degassing of solder paste is mainly to complete the stirring and degassing of the solder paste before packaging, and it is in a bubble-free vacuum state.

06. Common problems and solutions in the use of solder paste

• There are bubbles in the solder paste: It is recommended that customers extend the mixing time and vacuum time before packaging, and fill from the head of the syringe to minimize the generation of bubbles;

• The solder paste cannot be completely squeezed out, and some of the glue is still in the middle, which will cause the solder to break and bubbles to appear at the glue outlet;

• The syringe wall is not clean

In response to the common problems of solder paste dispensing, such as tin breakage, bubbles, and incomplete dispensing, Jingding Company has promoted a reverse scraper piston to the market. After long-term cooperation with customers and market verification, this piston can effectively avoid the above problems.

7. Product advantages

• High cost performance and excellent quality;

• New material, food grade, high cleanliness;

• High temperature resistance of 100 degrees, low temperature resistance of -40 degrees, drop resistance, ROHS certification;

• The product does not contain any additives to ensure the original quality of the glue;

• The piston does not rebound, is smooth and clean, and has no residue;

• A strong R&D team, a professional sales team, high-quality after-sales service, and fast delivery time.

Dispensing syringes are consumables, and a large amount of preparation is required for each use. We are the source manufacturer of dispensing syringes. If you need solder paste dispensing syringes, you can come to Shenzhen Jingding for procurement.