Many products are prone to process defects during glue dispensing, such as unqualified glue dot size, drawing, glue staining, poor curing strength and easy to fall off, etc. Therefore, to solve these problems, we should study the technical process parameters as a whole to find solutions to the problems. Here are a few key points to pay attention to in the glue dispensing process:

1、Dispensing pressure

The dispensing equipment or glue gun provides a certain pressure to the syringe to ensure the supply of glue. The pressure determines the amount of glue supplied and the speed of glue outflow. Too much pressure can easily cause glue overflow and excessive glue; too little pressure will cause discontinuous dispensing and leakage, resulting in product defects. The pressure should be selected according to the properties of the glue and the working environment temperature; high ambient temperature will reduce the viscosity of the glue and improve its fluidity, and the pressure value needs to be lowered at this time, and vice versa.

2、Dispensing amount

According to work experience, the diameter of the glue dot should be half of the product spacing, so that there is enough glue to bond the components and avoid too much glue.

2.1 The length of the dispensing time plays a certain role in the dispensing amount. In practice, the dispensing time should be selected according to the production situation (room temperature, viscosity of the glue, etc.).

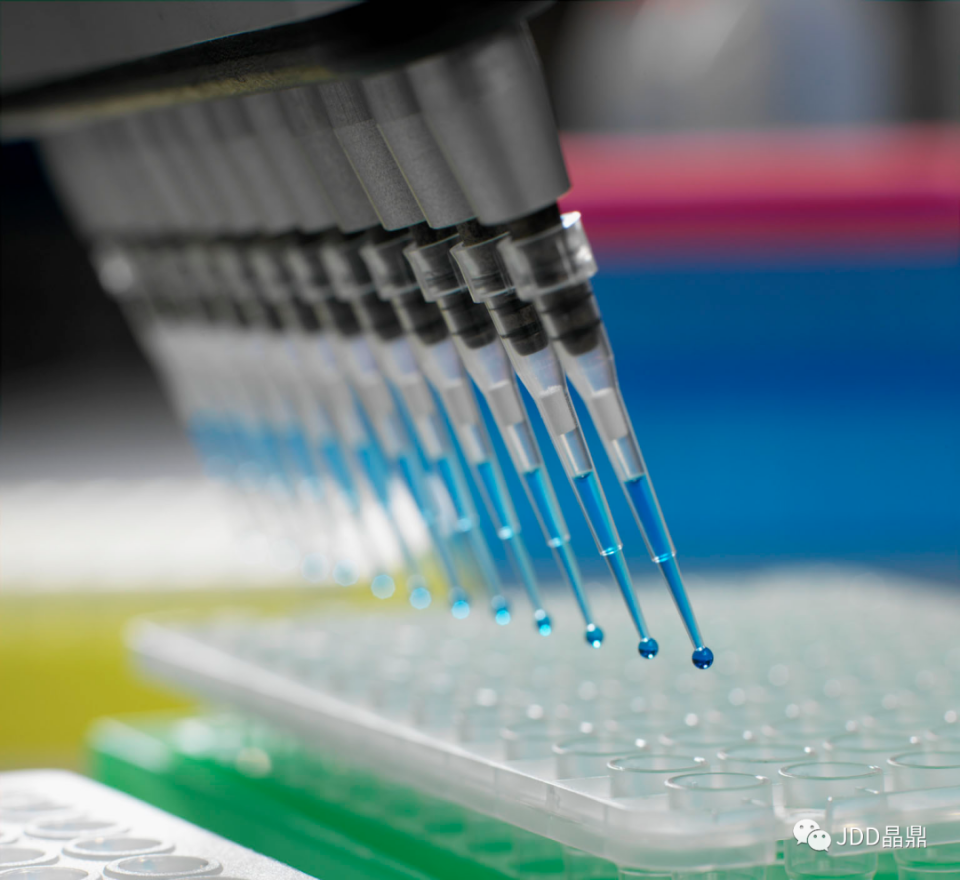

2.2 The size of the needle plays a certain role in the dispensing amount. In actual work, the inner diameter of the needle should be about 1/2 of the diameter of the dispensing glue dot. During the dispensing process, the dispensing needle should be selected according to the size of the product. Different needles should be selected for products with large differences in size, which can not only ensure the quality of the glue dot, but also improve production efficiency.

2.3 The correct needle should be selected for special glue, such as instant glue. For water-based instant glue, a safety piston and a Teflon-lined metal needle are used. For thick instant glue, a conical oblique needle is used. If flexibility is required, a PP needle is used. If the needle is not selected properly, problems of varying degrees will occur during use.

3、bubble

The problem of bubbles has always existed in the industry and cannot be solved in many projects. However, there must be no bubbles in the glue. A small bubble will cause the following problems during the production process: empty dispensing or insufficient glue, and rebound phenomenon; thus, the product needs to be reworked, scrapped or discontinued, which greatly affects the quality and output of the product.

JDD has developed different pistons for different projects to solve the corresponding problems. Taking the solder paste project as an example: JDD has developed a reinforced piston and an anti-scraper piston, which perfectly solves the problems of bubbles and rebound, while reducing the use residue, greatly improving the quality and output of the product.

4、Viscosity of glue

The viscosity of glue directly affects the quality of dispensing. If the viscosity is high, the glue dots will become smaller or even stringy; if the viscosity is low, the glue dots will become larger and may infiltrate the product. During the dispensing process, choose a reasonable pressure and dispensing speed for glues of different viscosities.

5、Glue temperature

For example: general epoxy resin glue should be stored in a refrigerator at 0-5℃, and taken out half an hour in advance when used, so that the glue temperature is consistent with the working environment. The use temperature of glue should be 23℃-25℃; the ambient temperature has a great influence on the viscosity of glue. When the temperature decreases, the viscosity increases, the glue flow rate decreases accordingly, and it is more likely to cause wire drawing. Under the same other conditions, a 5℃ difference in ambient temperature will cause a 50% change in the amount of glue, so the ambient temperature should be controlled. At the same time, the ambient temperature should also be guaranteed. If the temperature is too high, the glue point will dry easily, affecting the bonding strength.